It is the big aim of Lothar to reach a stage enabling him to design and build a high speed internal combustion engine which will join the worlds top control line combat engines. Lothar think that he has to employ advanced simulation methods concerning fluid dynamics, thermodynamics and and stress. In tandem with an engine test bench to get the input data for the simulation models as well as to verify the simulation results, Lothar try to reach this aim.

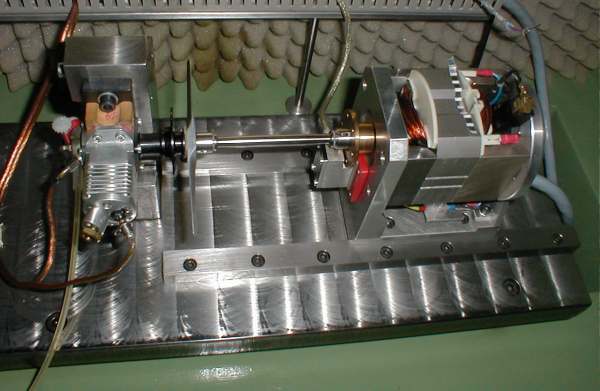

The picture below shows Lothars actual engine test bench.

This engine test bench employs the motor of a 750 Watt vacuum cleaner as a starter and brake-dynamometer. Engines could be driven in the motored condition with speeds up to 20000/min. In case the vacuum cleaner motor acts as a brake-dynamometer, the current of the stator electromagnets is adjusted to get the required brake torque. The electrical power which is induced in the rotor is extracted from the system using a resistor array, whereas the current serves as a torque-monitor after calibration.